The list provided below highlights some of those HVAC technologies with potential to increase indoor air quality. Every facility is different, and none of the technologies below is a one-stop solution. Investigation into a facilities needs and current HVAC design/systems plays a major role in the selection of an indoor air quality technology.

Ultraviolet Energy (UVGI)

Ultraviolet germicidal irradiation inactivates viral and bacterial organisms, which makes them unable to replicate. UV-C is the most used due to effectiveness. There are two common types of UV solutions used in HVAC systems.

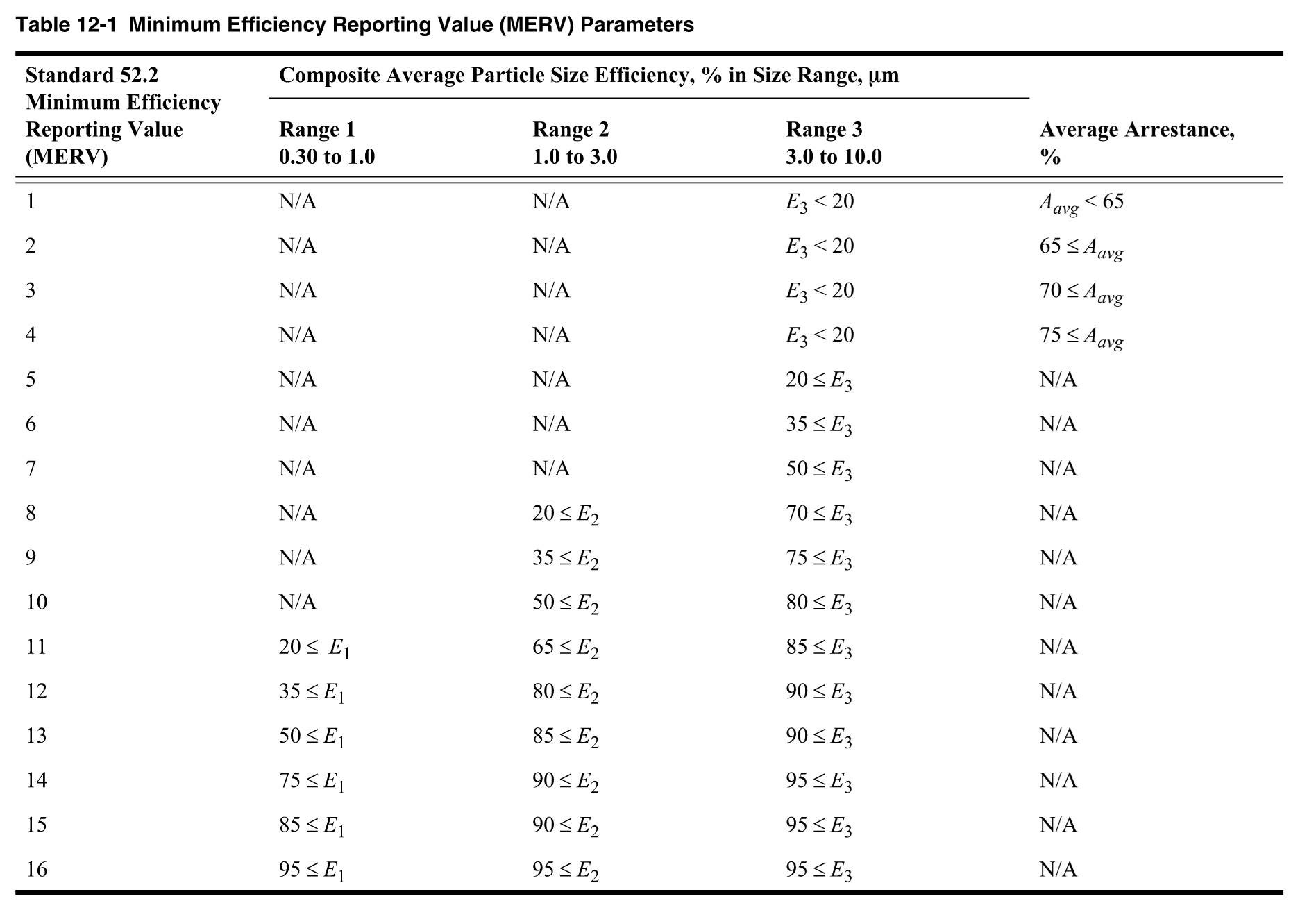

- In-Duct surface disinfection

- UV lights are installed near cooling coils and drain pans. Because the exposure time to the UV light is continuous, light levels can be low.

- Keeps cooling coil and drain pan clean and free from virus, bacteria, and fungus build-up despite cold and humid environment.

- Simple to install in new and existing systems, and inexpensive.

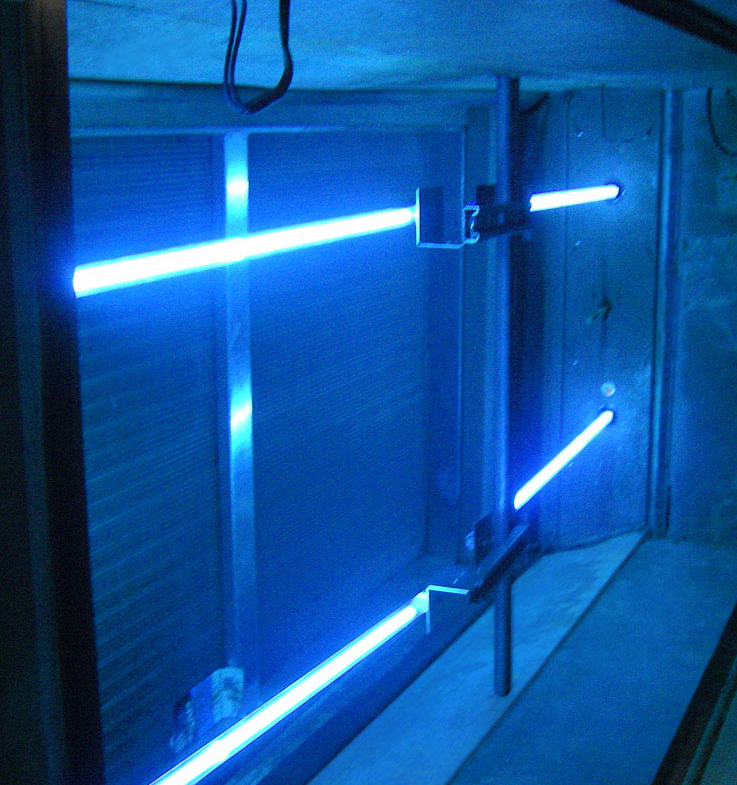

- In-Duct Air Disinfection

- UV light banks are installed inside ductwork. This system requires higher light levels, due to short exposure time with medium-high velocity duct systems.

- Mechanical filtration should be provided upstream of UV light banks in ductwork for dust control.

- Extensive renovations required for installation in existing systems. Can be expensive depending on CFM through ductwork and size of ductwork.

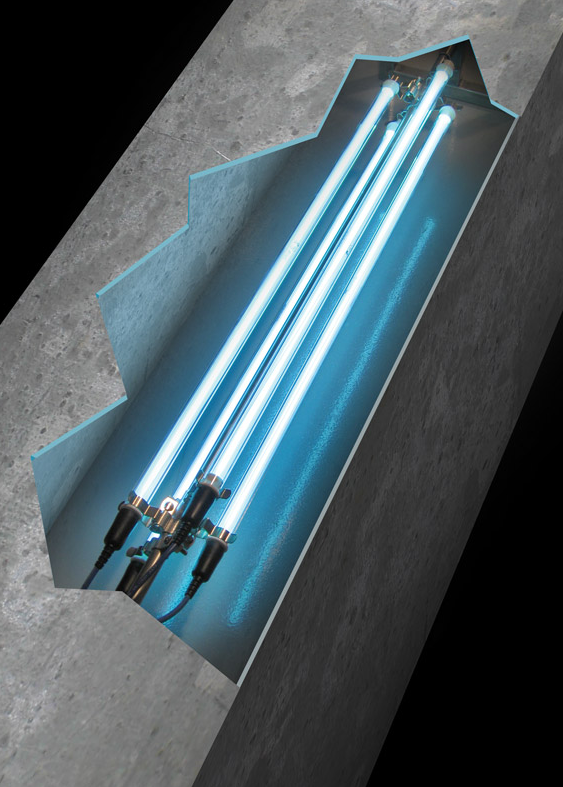

Bi-Polar Ionization

Bi-polar ionization technology produces positive and negative ions in the airstream. These ions can trigger cell oxidation, which can reduce airborne VOCs, odors, and carbon-based organisms. The oppositely charged particles also cluster into larger particles, which are more likely to be trapped in mechanical filters and removed from the airflow.

- Bi-Polar Ionization systems should be carefully analyzed to make sure they do not produce, as a by-product, an increase in the amount of Ozone inside the building being treated. Air cleaners that emit ozone by design should not be specified or installed.

- Bi-Polar Ionization technologies are simple to install in retrofits or new projects due to the constant creation of charged particles that move throughout the space via circulated air.

Gas-Phase Air Cleaners/Filters

This technology has been used previously in spacecraft and submarines, two applications where providing fresh outside air into an occupied space is impossible, and recirculating the existing indoor air is a must.

Sorbent cartridges that act as filters capture gas-phase contaminants in the airstream through adsorption. These cartridges typically load up with contaminants until saturated, then go into a regeneration mode, where warm air is run backwards through the cartridge to purge it of contaminants. The contaminated air is then exhausted from the building.

- Gas-Phase Air Cleaners can be installed in retrofit and new building applications with separate equipment or filter boxes outside of the air handling equipment.

- Reduction in total VOC and CO2 levels in typical office spaces have been shown to positively impact cognitive function.

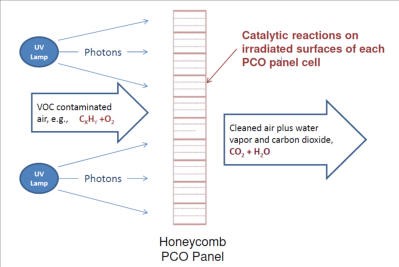

Photocatalytic Oxidation (PCO)

This technology combines a coated filter and UVGI light to create a chemical reaction on the surface of the filter. This chemical reaction produces an oxidizing agent that neutralizes VOCs and can help interrupt bacteria and virus life cycles.

- PCO systems should be carefully analyzed to make sure they do not produce, as a by-product, an increase in the amount of Ozone inside the building being treated. Air cleaners that emit ozone by design should not be specified or installed.

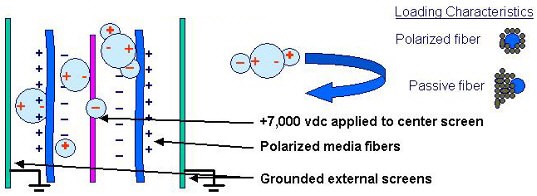

Polarized Filtration Media Technology

Polarized filtration media uses a generated electrostatic field inside of the filter section of an air handler to polarize the filter media and the particles that travel through the media via the airstream.

- Polarized particles are not charged, rather they have both positive and negative charges on opposite sides of the particle. Polarized particles bond together with other polarized particles and allow the filter media to collect those larger particles.

- Unlike some other technologies, polarized media efficiency increases as the filter becomes more loaded with particles, which can increase maintenance intervals.

Underfloor / Displacement Air Distribution Design

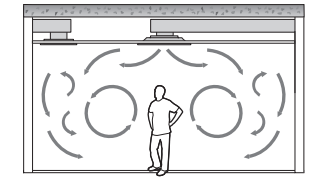

There are two main design strategies in terms of airflow in ventilated and conditioned spaces.

- The most common is classified as a mixing system. This mixing airflow design typically provides 55° supply air at the ceiling level. This high velocity air induces warmer room air below the ceiling, and mixes the entire room volume, providing an equal temperature gradient throughout the height of the room. This mixing process also causes a consistent contaminant concentration across the height of the room.

- Due to the nature of mixing systems, many more air changes are required to condition a large volume space.

- Most mixing systems are ducted above ceiling and modification of the layout of these systems is extremely intrusive and can be costly.

- Mixing systems typically provide individual controls for each enclosed office, but provide fewer control points for large, open office areas.

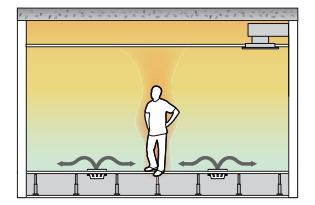

- Underfloor / Displacement Air Distribution systems typically provide slightly warmer air than a mixing system (63° or greater) directly to the occupied zone of the space. The occupied zone is the first 6’-0” measured from the floor upwards to the ceiling of the space. Delivering air directly to the occupied zone requires the air temperature to be slightly higher as to not cause a cold sensation for occupants.

- Thermal and contaminant stratification occurs due to supply air provided low in the space and return air at the ceiling or high on walls. Higher temperatures and higher contaminant levels occur at the ceiling and out of the occupied zone.

- While traditional Displacement Air Distribution systems are not very flexible, Underfloor Air Distribution systems are typically pressurized supply plenums, which provide unlimited flexibility in moving or adding air grilles when renovations take place or space uses change in a building. Each underfloor air grille is adjustable, allowing 100% occupant control of the temperature in their spaces, even in open office concepts.

- Underfloor Air Distribution plenums can also provide pathways for electrical and technology conduits, again allowing almost unlimited flexibility for changes in layouts.

- Underfloor / Displacement Air Distribution systems reduce energy costs compared to mixing systems by only conditioning the occupied zone. This becomes highlighted in high-ceiling, large volume space.