By Gary Hribar

President, Osborn Engineering

Design and Construction process has been around for over 4500 years and dates back to at least 2700 BC when the step pyramid for Pharoah Djoser was built by Imhotep, the first structural engineer in history and also known as “he who cometh in peace (ironically much like most of the design and construction teams of today).”

The Great Pyramids of the past, often up to 700+ feet long and 450+ feet high could take 20 years to build and involve thousands on the project team. The construction cost of a major Pyramid today would be projected at somewhere in the area of $ 4-5 Billion. And just as it would be in modern times, these were major design and construction efforts.

I often wonder if Imhotep was selected through an RFQ or an RFP. Did the Owner’s Rep have full control or did he have to check with the Pharaoh from time to time? Did he lead the team of workers (nearly all slaves) in annual value engineering sessions? Did the Pharaoh lead the partnering sessions or did Imhotep? Did they have a Contractor Controlled Insurance Policy (CCIP) or an Owner Controlled Insurance Policy (OCIP) for Imhotep’s miscalculations? Did they do an early cost estimate and what was the look on the Pharaoh’s face when they told him that it was going to take an extra 12-15 years and cost $3-4 billion dollars more than expected? Lastly, was there ever a proper sign-off on the DD package?

The big question that rolls around in my mind is, ”Exactly how far has our industry progressed in the last 4500 years?” In the areas of science it certainly has progressed through the years with a more efficient workforce (no more slaves) and better technology, including multiple advancements in heavy building equipment for ease of construction and most recently, 3D Building Information Modeling (BIM) for design and construction information development. These are technological tools or mechanical items that can do things better, faster, cheaper. However, in the more artful areas of process improvement such as enhanced project team structure and associated dynamics, expectation alignment, and communications and other key areas, I am concerned that we have not advanced enough as an industry.

Our industry is much like today’s other societal and industry dynamics where decision makers are influenced by trends and sound bites, at times motivated by politics and impatience, and are looking for easy to describe solutions and quick returns for a very complicated business.

For example, Design Build or IPD process is no more the panacea for project success than hedge funds were for investors when they hit Wall Street in the 1980s. Every owner, every project dynamic and the associate project purpose and goal is different, and as such, requires a well thought-out approach and an interest and ability to address the deeper more meaningful project drivers. These unfortunately do not come in a package or a sound bite. Below, I briefly touch on some of the finer points that you are not likely to see in any sound bite, project handbook or construction journal as well as the associated success factors that typically never get discussed, defined or even worse, understood. These are mostly the human and subjective elements (the art forms) that have a large roll in driving overall project success.

Linking the business strategy to project delivery

More times than not, the client is uncomfortable with too strong of a link from the design and construction team to the in-house business strategy. Most often the design and construction team is on a Need to Know Basis. This phenomenon causes a disconnect in decision-making, especially when alternate scope directions are being considered. To my way of thinking, unless there is a confidential aspect to the Business Strategy, which can be covered under a Non-Disclosure Agreement (NDA), it must be linked to every decision on the project from start to finish to make sure that all the goals and objectives are in tact. Most capital projects have spends in the million of dollars. As such there are many ways to reduce cost while minimizing or protecting the goals and objectives of the business strategy. Additionally, there is a strategic aspect to the business strategy and there is a tactical aspect to the business strategy. These are two very different components. Each one of these drivers must be examined separately. I have been involved with many projects where the overall spend was over $ 100M, and at the end of the project the business strategy was in some way compromised more than it needed to be due to a poor link back and monitoring of the project against the business goals. Had business strategy been continually maintained as a driver for the design and construction project, the client could have likely avoided the degradation that occurred.

For every project, document the key aspects of the business strategy (both strategic and tactical) and keep them at the forefront of the project team throughout the execution of the project to ensure the team is meeting business goals and objectives as well as known deviations.

Establishing the team and the project foundation – it is all about the money!

Most projects (45-90% depending on which historical report you believe) start or at least encounter a project budget that is less than what is required for the desired scope. This by definition means that the project is on a weak foundation. Why anyone would think a design and construction delivery process is the solution for this issue, is beyond me. Have any of you been an investor or a developer and had your money at risk? The dynamic that the money creates is a real one and if not managed appropriately can put the project on a very weak foundation right at the onset.

Due to the amount of less than satisfactory outcomes, coupled with a sense of not that much advancement in the industry, owners are often searching for the latest delivery method as a solution ... Design Build, IPD, LEEN, etc. In the last 15 years there have been many new models that have been tried….at least in Ohio. Without having a full set of data to understand the true success…for example, how is the facility going to hold up over the next 30- 50 years, how would we know, at this point, if the models are successful or not? And as stated earlier, the latest delivery model is only one small aspect that dictates the strength of the foundation for a project.

In many cases, too much focus on the money early in the project delivery starts to negatively impact the assembly of the team, support resources and ultimately the key early project decisions. Focusing on the money too late in the process can lead to missing the target and starting over. Since the 1980s, I have worked with several owners that have said, “I do not want our creative thinking to be stifled by the money available.” This can be good process if one understands the context of the exercise or this can be very detrimental to the project as interesting reactions begin to unfold when there end up being budget problems. Either way, understanding the impact of budget versus actual costs and being able to manage this dynamic for a strong project foundation is critical to a project's ultimate success.

As opposed to only a money focused diagnostic as part of a routine look at the project, one should implement a foundation analysis as they continue throughout the project execution….Is the team working well together, is my process fluid, have a I had to restart and stop, is my project aligning with the business strategy, do I feel that the process and the project is efficient, do I still have major gaps or risks, am I gaining ground on the money issue or losing ground? Am I losing trust in my team and why? These are all questions which should be asked and all have to do with the complete foundation of the project. This type of overall analysis will likely lead to a quicker solution to the money problem, if there, in fact is one.

Understanding the owner’s rep, design team and construction team culture, motivations and capabilities – difficulty for any firm to admit a lack of capability or lack of understanding in front of the owner

Project teams get assembled in wide variety of ways. Sometimes the owner’s team managing the group wasn’t the one that picked the team. Often times the reason the owner picked a certain group is that they were interested in getting a certain capability or expertise with the firm. Sometimes Owner's pick on a past project or series of projects; sometimes pre-existing friendships and politics drive the choice; often times cost is a factor. And on and on in terms of the way teams get assembled. Once the dust has settled and the team is in place, it is critically important to behave like a team and develop a very candid and open dialog with the owner, not unlike a coach on a baseball or football team. Team members must develop mutual respect. I always get a kick out of making a comment on how something might be important, only to have one of the team members respond with, ”Oh yes we always do that!" Somewhere between constant sales mode and responding in a way as to make sure that they point does not get discussed appropriately as a team any further. It takes a lot of confidence, experience and commitment to the owner to put your company’s business interests, position on the project and vulnerabilities aside on behalf of a project. Project team dynamics can foster this or sometimes make it very difficult. This gets especially challenging when the team and/or the owner starts to lose confidence or judge the capability of a particular team member in the middle of the project. Very few times on a normal project delivery does the team and the client have what would be akin to 6 month or 12 month performance reviews. The team giving it's perspective; the client giving theirs; and then a dialog to discuss joint conclusions.

At a minimum, a candid entire team principal’s dialog with the owner must take place at regular intervals throughout the project. I have seen many owners say they are going to do this and only about 5% of the projects that I have been on have followed through with this in a meaningful way.

Understanding the level of sophistication required for cost control and suppression

Anyone that is a veteran in the design and construction industry knows that if you impose Liquidated Damages onto a project bid specification, 90% of the time the contractors will include the Liquidated Damages in the Bid. Does it make sense to anyone that the owner would pay for their own Liquidated Damage and worse yet, pay a contractor and their subs for LDs if they are never enforced. It happens quite often and is an example of a very heavy handed approach and not so useful way to control costs.

Another example that is quite common is suppression of design fee. So in the case of structural engineering, at what point have you driven the fee for design down so far that the most efficient method of design is to make more conservative assumptions and calculations (that can be done with less study and analysis and conserving fee), resulting in higher structural steel and foundation costs ultimately for the owner. This can also happen.

Controlling and suppressing cost requires a level of sophistication that most owners are not willing to fund. Regular cost estimating is only part of the solution. Understanding what is driving both the soft and the hard costs on the project and what the alternatives are in the categories that have significant cost movement, are most critical. While there is not a lot of relief for projects that are 25-50% over budget. Most projects are within striking distance of the budget and an experienced team approach, again with all eyes on the original business strategy, can usually resolve the budget to actual cost difference.

Establishing a much more sophisticated approach to cost control and suppression as part of the normal design and construction process is advisable. This can be a more limited group and can involve multiple skill sets, however, to be effective, must be included as part of the process and not the hammer to throw the regular process into a tailspin.

The client personality (that pays the bills) vs 'I hired you (vendor) as the expert' dynamic – does the emperor have clothes on or not? And is the unstated consultant standard of care perfection?

Has anyone ever played basketball? Have you ever turned the ball over? I think that a good turnover number for an NBA team in a game is less then 10. Does anyone think that designing and constructing a building is easier than basketball? Especially, in light of fast-track schedules and fee suppression which creates down-side pressure on what used to be much stronger QA/QC process in the industry. Again due to project horror stories, tight budgets, stressful demands from above and many other factors, the spotlight turns quickly on the vendors and what was it that they didn’t execute to perfection. Gross negligence and incompetence aside, most well established firms perform within the industry standard of care. If you put the development of design and construction in the same fluid context as a basketball game or for that matter, actions on a battlefield, the perspective of an error or the hierarchy of the team would be in a better context. Diagnostics and reflections can take place in different venues - post project and periodically and as often as they are productive for the completion of the overall project. Equally challenging to the aforementioned standard of care expectation is the notion of being able to articulate to an owner, when they are making a bad call, without compromising the vendor business position. Vendors are extremely careful with this, and I am not sure if there is a solution given the human nature factor…..”Since I am paying the bills, my actions and directives are a given…..Is that clear?” “Crystal Sir!”

Has anyone ever played basketball? Have you ever turned the ball over? I think that a good turnover number for an NBA team in a game is less then 10. Does anyone think that designing and constructing a building is easier than basketball? Especially, in light of fast-track schedules and fee suppression which creates down-side pressure on what used to be much stronger QA/QC process in the industry. Again due to project horror stories, tight budgets, stressful demands from above and many other factors, the spotlight turns quickly on the vendors and what was it that they didn’t execute to perfection. Gross negligence and incompetence aside, most well established firms perform within the industry standard of care. If you put the development of design and construction in the same fluid context as a basketball game or for that matter, actions on a battlefield, the perspective of an error or the hierarchy of the team would be in a better context. Diagnostics and reflections can take place in different venues - post project and periodically and as often as they are productive for the completion of the overall project. Equally challenging to the aforementioned standard of care expectation is the notion of being able to articulate to an owner, when they are making a bad call, without compromising the vendor business position. Vendors are extremely careful with this, and I am not sure if there is a solution given the human nature factor…..”Since I am paying the bills, my actions and directives are a given…..Is that clear?” “Crystal Sir!”

Some owner’s take on a certain culture with this, and they quickly get branded in the industry as……Well you have worked for them, you know what they are like…………as much as any vendor would dare to say, given the risk of negative information getting back to the client.

Self-reflection is a good way to make sure your objectives are met and your investments are being deployed wisely. Additionally, deal with an error in context and keep the project foundation strong throughout the resolution of the error. If you feel the standard of care drops below the acceptable level, discuss the situation first as a global look at all project events and actions. Put yourself in the other person’s shoes often as the project progresses.

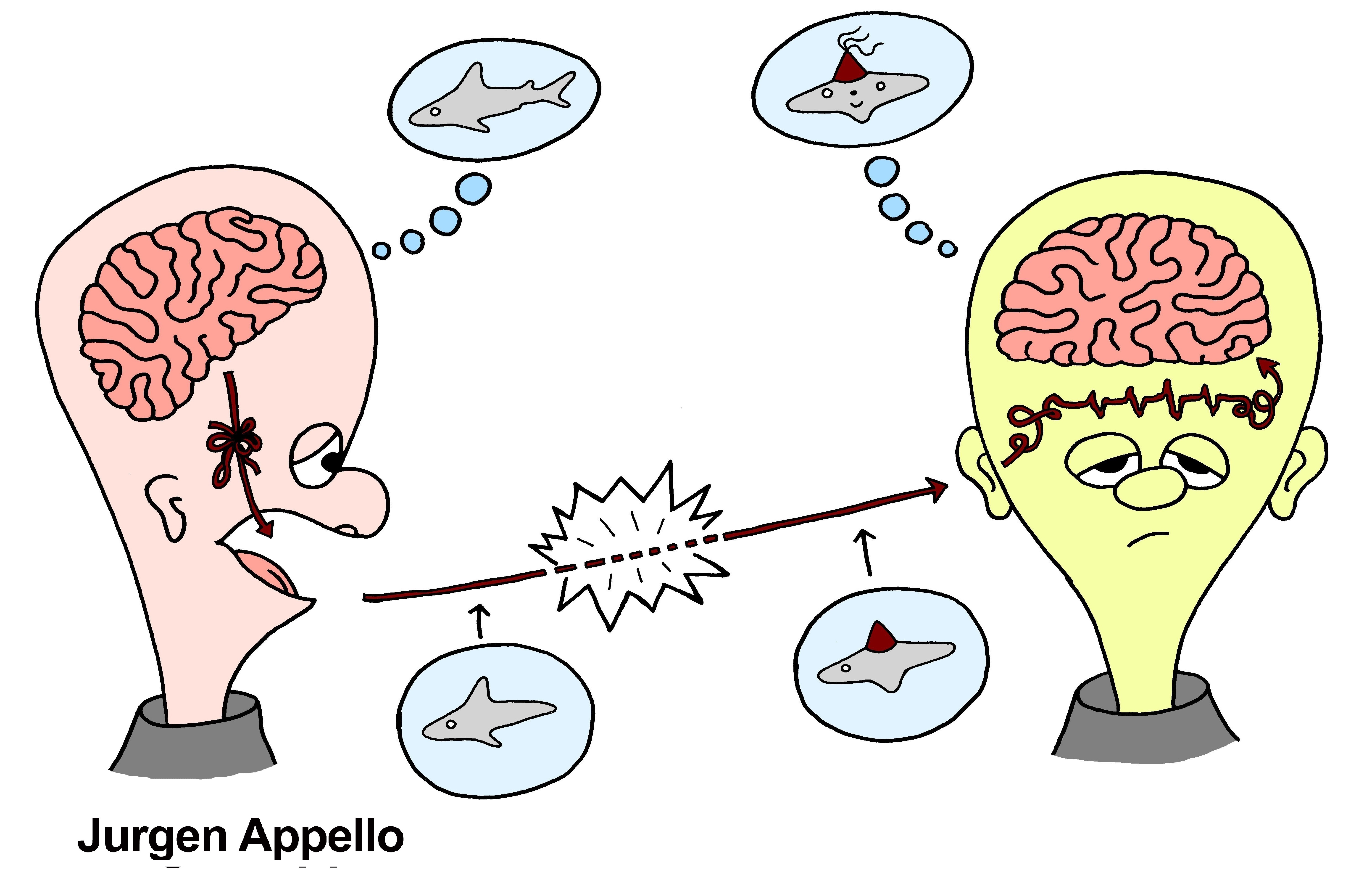

Effective and real-time project communications - everyone says it is important, however, not every project has it.

Unfortunately, Project Communications is the easiest topic for everyone to agree that it is critically important, and therefore, execution is almost taken for granted. I like to monitor project group email communications as a barometer of how the team is communicating. Additionally, if our team is not linked heavily and often to all levels of the project team with cellular communications, it is usually a sign of inadequate communications. In today’s world of technology, there is no excuse for inadequate communications on a project.

However, given the introverted nature of our practice, the hierarchy of the project and many of the factors discussed in this paper, often times there is failure to communicate. One area that provides and indicator on project communications is meeting productivity and conference call productivity. If there is a problem with either of those (for example needing several meetings or calls to resolve a single issue), it is usually an indicator of a communication breakdown. Multiple occurrences of this are a sign that there is a systemic breakdown in communications.

Again, given the right diagnostic focus, effective project communication is something that can be monitored, enhanced and discussed often during the life of a project.

Monitor effective communications on the project just like you would monitor drawing development, the cost model or the completion of construction. Anticipate that many adjustments will need to be made along the way.

If there is one take-away from my message, it would be that successful design and construction project delivery in its highest form is driven by the factors that the team controls and is a balance between art and science. However, all of the fine points discussed above must be considered and incorporated in some way.

Gary Hribar is President of Osborn Engineering and a 32-year veteran of design and construction and a life-long student of project delivery. He has been involved with billions of dollars of design and construction with a wide variety of clients including federal, state and local government, private sector, public-private ventures and not-for-profit organizations. His project experience includes major infrastructure, energy management, buildings and systems, high technology environments and athletic, healthcare, waterfront and education facilities.